Contractor’s investment will benefit local vineyard and orchard owners

18th June 2024

A new, Northamptonshire winery will accept its first grapes during this year’s harvest, and the owners have also invested in a fleet of modern vineyard machinery which will be available for use by other growers through a new contracting service. David Williams reports.

“Plenty of excellent contractors already offer their services to growers in the South East,” explained fifth-generation farmer and second-generation vineyard owner, Will Croxford, of Croxford Wine Estates.

“However, although there are several long-established vineyards as well as newer ventures in the Home Counties, there isn’t the same access to modern, specialist machinery. Windows for vineyard operations are typically short, and we have found that contractors based further away would rather work within a short travelling time of their bases, allowing them to serve more growers during windows available, rather than spending unproductive time travelling.

“Our new winery is designed with capacity not only for our own crop, but also so we can provide a contract wine making service for other growers in our area. Therefore, it makes sense for us to utilise our fleet of modern vineyard and orchard machinery to offer growers the full package; from initial planning, preparation and planting to seasonal management, plus harvesting, processing and bottling.”

The new Nene Valley Winery is just outside Northampton, and has initial capacity for 250,000 bottles annually, with future increases planned. It is owned by, and operates as a partnership between, Croxford Wine Estates and Patch Lodge Estate.

High-end wines

The vineyard contracting operation is owned and run by Will Croxford and his partner, Victoria. The Croxford family farms just over 100ha, of which 10ha is down to vines planted in 2019–20 by the previous owner, and which produced their first harvest of 24t of grapes for Will last year.

Of those, 16t were sold under contract and the rest were bottled to launch the family’s own Robinson Croxford wine brand. The high-end quality market is being targeted and renowned wine maker, Salvatore Leone is working with Nene Valley Winery to ensure best possible results from the start. Supply will be mainly to trade, with the focus on sparkling wines from Chardonnay, Pinot Noir and Solaris varieties, and still wines from Bacchus and Pinot Noir Précoce.

A 10-year plan for steady growth of the enterprise includes establishment of additional vineyards to produce grapes for the onsite winery. The Nene Valley has a rich history of wine making, including some of the largest vineyards outside Italy established during Roman times. There is no shortage of suitable land in the area belonging to extended family and neighbours.

Ensure timely operation

“We knew we needed modern, reliable machinery to operate in a timely manner and ensure grapes of the highest quality for our winemaker, so investment was essential.

“We also recognised that selecting the right equipment would give us spare capacity to provide services for other growers too,” stressed Will. “As far as I’m aware, we are the only business offering the full range of vineyard services including making and bottling the wines.”

Latest machinery and techniques

Will’s specialist narrow tractors are sourced from a local dealer, and most of the new vineyard machinery is from Kent-based orchard and vineyard machinery manufacturer and importer, Kirkland UK.

“My agricultural background meant I was already familiar with the benefits of precision farming techniques, including reduced operating costs and lower environmental impact,” Will continued.

“I’m keen to utilise these techniques for vine growing too, including variable rate spraying where chemical or nutrient application rates are matched to the needs of the crops, and spot spraying where treatments are only applied where needed.”

Reduced chemicals, no efficacy loss The 1,600-litre Friuli two-row sprayer selected by Will features a drift recovery system. “We can significantly reduce chemical usage and costs, without compromising on application rates and risking reduced treatment efficacy or creating resistance,” he explained. “We apply at full rate, but spray that misses the leaves or berries is sucked back in through the recovery system to be applied again, rather than ending up on the ground or drifting across neighbouring rows and over-dosing the vines.

“Typically, we can achieve 40–50% chemical savings and an equivalent increased sprayed area between refills, but that all depends on the conditions. It’s more environmentally friendly than a conventional sprayer as more chemical ends up where it’s needed, and cost savings can be considerable.

“We expect annual savings of £7,000–£8,000 for our own vineyard, and customers using us for their applications will benefit from similar savings too, depending on the conditions and sprayed area. This could potentially ‘pay’ for us doing the spraying for them on a contract basis, rather than doing it themselves with a conventional sprayer.

The drift recovery system also increases flexibility in terms of weather windows. “We usually wouldn’t use conventional sprayers when wind strength exceeds 7mph, but the drift recovery system allows us to work in winds up to 12mph,” added Will.

The sprayer has twin axles and four wheels which spread the weight of the tank across a large surface area, reducing rutting and compaction. “The sprayer came with a premium price tag, but we believe the advantages it offers will benefit us for our own crop treatments, and also appeal to our customers,” he confirmed.

Efficient, accurate trimming

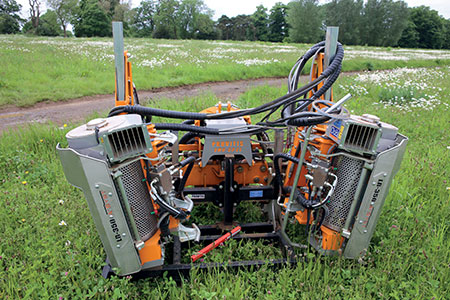

A Provitis two-row trimmer has also been purchased. With four cutting faces and rotating blade cutters, it mounts on the front of the tractor and trims branches and foliage projecting beyond the desired vine row width. “Ideally, we would carry out three to four passes per year, and that will maintain a tidy box shape ideal for spray treatments and harvesting,” suggested Will.

Foliage control improves crop development and ripening

The rotary leaf stripper is also from Provitis. Mounted to the front of the tractor, it uses a fan to create suction and draw excess foliage into pairs of rollers that gently strip the leaves from the vine. “Removing excess foliage means the growing fruit intercepts extra sunlight, and it also improves spray treatment efficacy as coverage is more even,” explained Will. “It’s extremely gentle, and there is no damage to the berries.

“We regard foliage management as an area of increasing importance as more customers realise the benefits. The Provitis machines weren’t supplied by Kirkland, but we are already discussing additional solutions with the Kirkland team.”

Maximising cover crop benefits

As cover crop popularity increases, different methods of managing the beneficial vegetation are of interest. “We’ve seen many customers using cover crops as an alternative to grass between vine and tree rows,” explained Kirkland UK sales manager, Tom Wheatley. “Mowing or mulching it is an option, but during the season this damages the beneficial insect habitat, so Orizzonti Bio Rollers are a popular alternative. They are simple and cost-effective, and are pushed along in front of the tractor, where they roll and flatten the cover crop, while blades on the roller cylinder have a crimping effect.

“The flowers and seeds remain rather than being destroyed by mowing, then at the end of the season the residues are pulverised as usual. Being able to maintain areas between the vine and fruit tree rows without losing benefits of expensive cover crops is a significant advantage and we believe that Will’s Bio Roller contracting service will be in demand.”

Under vine management

Solutions for under vine management are of growing interest as the industry moves away from chemical ground vegetation control. The Orizzonti Multy 2 mounting system is compatible with a wide range of attachments, from mechanical cultivation heads to shallow plough shares, rotary mowers, bud rubbers and powered rotary heads. “It mounts on the tractor front linkage, and the base unit comes with an integral hydraulic drive system which means attachments tend to be simpler and cheaper than competitor versions and they are easier to swap,” explained Tom.

Will agrees: “We considered alternatives from other suppliers too, but we preferred the design of the Multy, and it’s supplied and backed up by Kirkland, which is an advantage.

“We like the Ecology head, which features a rotating horizontal shaft with durable nylon cutting lines to efficiently clear dense vegetation between and around vines without damaging the trunk, and it also removes low shoots at the same time.

“With the two cutting heads working under vines on both sides and a mower at the rear, we achieve a very tidy finish in one pass, making it an efficient and cost-effective operation.”

Mechanical harvester maximises quality for processing

Will has also invested in a Gregoire Trailed Grape Harvester, from Kirkland. “We started importing Gregoire harvesters four years ago, and offer the full range including trailed, de-mount and self-propelled models to cater for all types and sizes of operation,” said Tom. “Back-up for these machines is critical, so we carry every part likely to be required in stock in the UK, and our workshop team is fully trained to service and repair the machines so that downtime is minimised.”

Before ordering his Gregoire trailed grape harvester, Will visited several vineyards in France to see the main makes and models in action. “They each had advantages and disadvantages, but we liked the flexibility of the Gregoire machine, and the gentle way it handled the berries.

“A big advantage is that the de-stemming system can be quickly and easily engaged and disengaged in the field, making it easy to adapt to changing conditions. If grapes are very ripe and come away from the stems easily, then the destemmer is lifted out of work to minimise berry damage.

“Another good feature is that tailings are lifted over the front of the machine, making it easier for the operator to monitor what is happening from the tractor cab. If too much is coming over, then the speed can be reduced, and the settings altered to correct the situation.”

Cost-effective

Will said that compared to hand harvesting, the mechanical grape harvester is a cost-effective option that can also improve quality of harvested fruit. “In the Home Counties we don’t have the number of regular pickers that are available to growers in the South-East. This means it’s even more important to make the most of every weather window when crops are perfectly ripe. Using the Gregoire harvester, we can harvest the required tonnage of grapes much quicker than a team of hand pickers, so they can be transferred to the winery for processing before the condition deteriorates.

“Typically, machine harvesting is slightly harder on the crop than hand picking so there is more damage, but the reduced time between harvesting and processing more than compensates. Another advantage is that we retain the grape juices, so these are available for processing too adding value to the machine harvesting technique.”

Contract machine harvesting will be offered to growers nationwide. “We bought the Gregoire harvester primarily for our own crop, so we can offer very competitive prices for our service,” he explained. “Typical hand harvesting cost in our area is approximately £300 per tonne, but we can offer machine harvesting for approximately £100 per tonne, depending on the situation. It’s expected to be popular and will reduce the stress of trying to assemble teams of experienced pickers who know what they are doing.”

Reliant on a good dealer

Working with Tom Wheatley and the rest of the Kirkland UK team made selecting equipment for the contracting fleet very straightforward, said Will. “We found the team easy to deal with. Back-up in the event of problems occurring is going to be critical to our success, especially providing a contracting service for other growers as we don’t want to let anyone down.

“We know that we can call Tom, or Kirkland partner and product specialist Scott Worsley, at any time. Soon after delivery, when a minor teething issue occurred, Scott understood exactly what we were talking about and provided a solution by phone. The parts team knows the products inside and out, and anything we need that is ordered by the evening will be delivered the next day.”

Fully flexible contracting service

Will is confident that his family’s new venture will prove successful. “It’s all about two families with a passion for English wine working together. The winery and contracting business complement each other, and it means we offer the full process from planting vines to managing and maintaining the vineyards and producing quality wines.

“News of our new contracting service has been welcomed by growers in the Home Counties, and we will continue investing in additional machinery and equipment to ensure we offer the best possible service.”

Read more machinery news